Solid Edge

Solid Edge 2021 : All the features you want. All the value you need.

Solid Edge 2021 provides the speed you need to get the most out of your entire engineering process—maximizing your productivity while decreasing your costs.

- Design at the speed of creative thought, with new subdivision modeling, lightning-fast reverse engineering, a new user interface powered by artificial intelligence and an intelligent 3D model search engine

- Enable fast, accurate 2D layout of industrial control panels with new cabinet panel design capabilities

- Optimize and validate designs with tighter integration between flow and structural simulation

- Speed up NC programming with a searchable postprocessor database, new fast roughing and adaptive milling

- Produce high-quality documents and illustrations, faster…directly from your 3D models

- Take control of your data, saving time and money, with new rapid concept modeling and shape search capabilities

- Expand your options with new tools for cloud-based collaboration

A complete product development portfolio

Solid Edge is a portfolio of affordable, easy-to-use software tools that address all aspects of the product development process. Solid Edge combines the speed and simplicity of direct modeling with the flexibility and control of parametric design – made possible with synchronous technology.

Complete Product Development Portfolio

A complete set of solutions

Solid Edge provides users with a full portfolio of solutions to meet a wide range of business needs. Solid Edge not only offers rich design solutions, but scalable solutions for simulation, manufacturing and data management as well.

Speed, flexibility and next generation design

Everything you need in a design solution, plus everything you want, including synchronous technology, generative modeling, additive manufacturing, and reverse engineering.

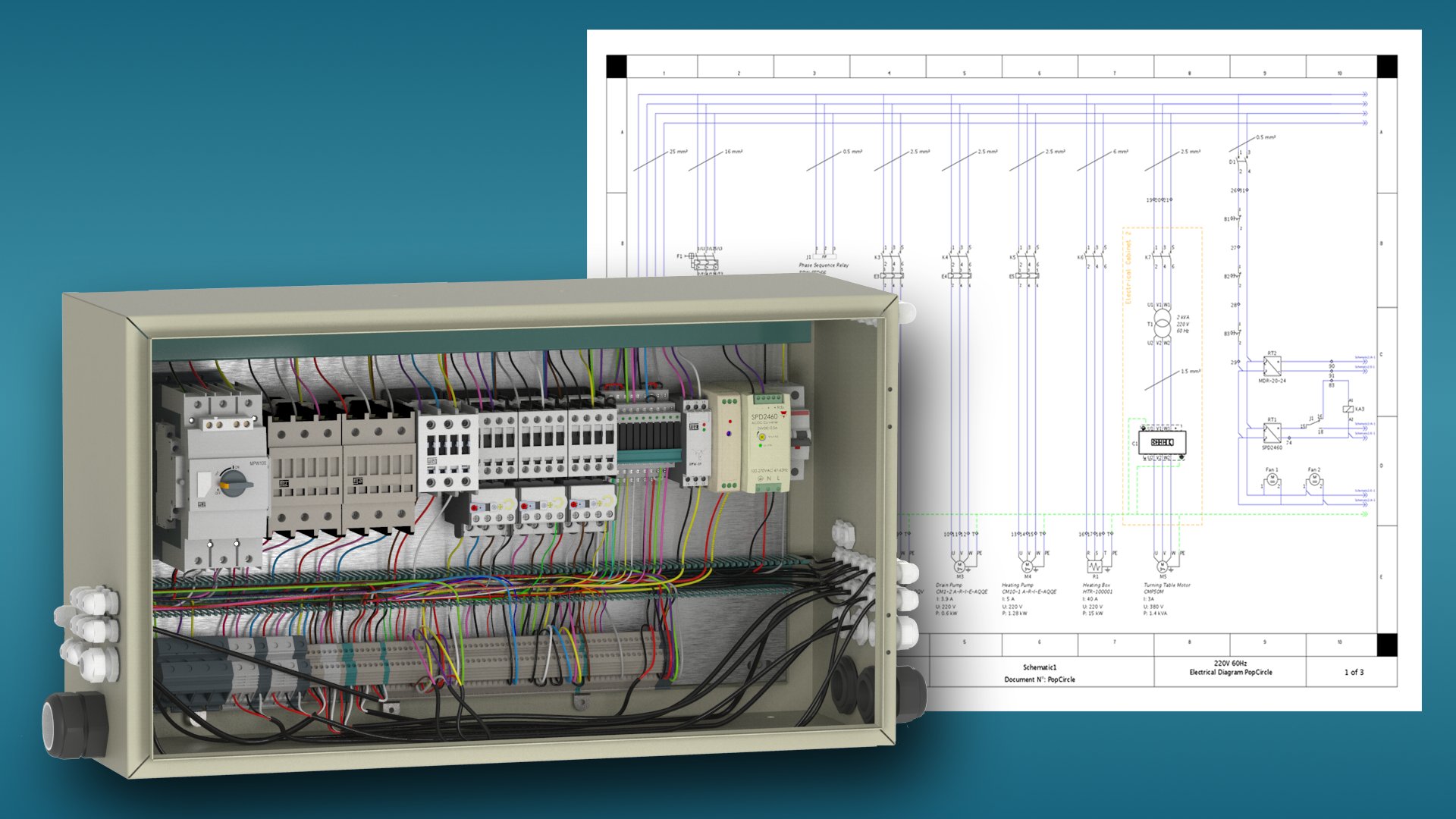

Integrated electrical design

Overcome electrical design challenges early in the design cycle. Solid Edge electrical design software was developed to satisfy the requirements of companies where ease of use and value are as important as functionality.

Scalable simulation software that drives design

By starting simulation early in design, changes are made when they are easiest, time-to-manufacture is shortened, and cost-to-manufacture can be reduced.

Scalable data management

Data management that meet the needs of all manufacturers, from startups and very small firms to larger manufacturers with distributed operations.

Traditional and additive manufacturing

Solutions to support a variety of traditional and new manufacturing techniques, including machining, welding, sheet metal, molding, and additive manufacturing.

Dynamic technical publications

Quickly create many types of technical documents, from simple illustrations for end user manuals to interactive technical documents for manufacturing and service.

Cloud-based collaboration

Share your design and manufacturing data securely throughout the product development process with the free Solid Edge Portal.

Data Management

Scalable CAD data management solutions that meet the needs of all manufacturers, from startups and very small firms to larger manufacturers with distributed operations.

Manufacturing organizations can struggle to work effectively with the fast growing volumes of data that they create when designing and manufacturing their products. Research from industry analysts shows that manufacturers who implement effective solutions for are:

as likely to be “very effective” at finding the data they need.

as likely to be “very effective” at managing their design projects

as likely to be “very effective” at sharing data with others

as likely to be “very effective” at providing the correct data to manufacturing

Rapidly take key actions to improve product development performance

A scalable set of data management solutions that meet the varying needs of small to large manufacturing organizations who may design simple or very complex products. These Solid Edge CAD data management solutions enable you to rapidly take the key actions identified by industry analysts that lead to improved product development performance:

- Secure and control your product data and processes

- Enable rapid retrieval of the correct information to improve efficiency and facilitate re-use

- Share product information and collaborate with downstream functions such as manufacturing to improve quality and reduce costly errors

- Follow industry best practice workflows for engineering change and release to manufacturing

Solutions range from integrated data management capabilities that are included with Solid Edge, to the comprehensive CAD data management and product lifecycle management (PLM) capabilities of Teamcenter®.

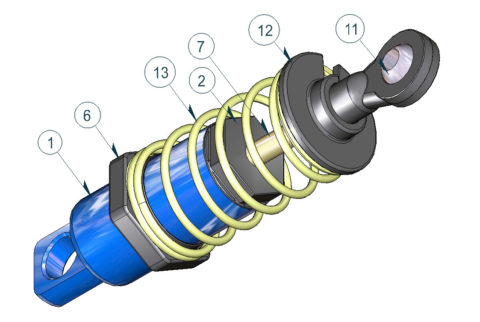

3D Design

Industry-leading 3D design software

Solid Edge uses synchronous technology to help you accelerate product design, make revisions faster, and improve design data re-use. With faster 2D drafting, best-in-class sheet metal design, flexible part and assembly modeling, built-in photo-realistic rendering, and unmatched mobility, Solid Edge lets you design at the speed of creative thought.

- Augmented reality

- Model Based Definition

- Next Generation Design

- Synchronous Technology

- Sheet Metal Design

- Subdivision Modeling

- Assembly Modeling and Management

- CAD Drawing & Drafting

- 3D Rendring

- Cloud-enabled Design

- Modular Plant Design

- Solid Eage OEM

Best-in-class 3D design

Next Generation Design

The future of 3D product development—generative modeling, additive manufacturing and reverse engineering, enabled by Convergent Modeling technology.

Synchronous Technology

Combining the speed and simplicity of direct modeling with the flexibility and control of parametric design.

Sheet Metal Design

Build complete sheet metal design system with support for the entire design-through-fabrication process.

Assembly Modeling and Management

Superior assembly performance, whether you’re dealing with a few components or hundreds of thousands of parts.

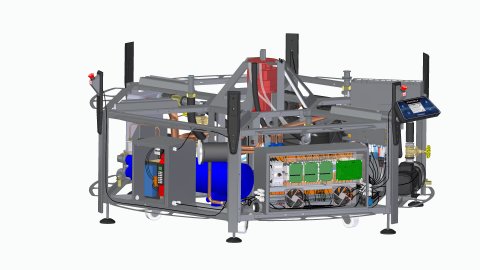

Modular Plant Design

Streamline your P&ID workflow process with database-driven access to pipe specifications.

CAD Drawing and Drafting

Drawing layout, detailing, annotation and dimensioning controls that automatically comply with mechanical drafting standards.

Photo-Realistic Rendering

Photo-realistic images and animations from within the modeling environment to bring your models to life.

Cloud-ready Design

Easy access across different devices, instant configuration of your CAD environment, and quick sharing of data with team members, suppliers and customers.

Augmented Reality

Bring ideas to life with design visualization; validate digital designs in a physical environment.

Model-Based Definition

Realize significant gains in manufacturing productivity; spend less time on engineering documentation using fully digital processes.

Subdivision Modeling

Develop distinctively unique products based on organic shapes without the need for expert knowledge.

Adaptive UI

Improve productivity with new adaptive user interface capabilities that harness artificial intelligence to predict next steps based on user behavior.

Parasolid Inside

The engine behind Solid Edge is Siemens Parasolid® software, the most widely used computecr-aided geometric modeling kernel in the industry. Parasolid delivers 100 percent 3D model compatibility between product development applications. By enabling the creation and modification of digital 3D models, Solid Edge delivers on the Siemens commitment to provide digital transformation capabilities to its users. Digital transformation allows even the smallest organizations to leverage technology to level the playing field with large enterprises.

There’s a Solid Edge 3D Design package that’s right for you.

Choose the features you want at the value you need.

Solid Edge Design and Drafting

Get started quickly with our most affordable 3D CAD package! Solid Edge Design and Drafting includes basic part and assembly design, automated drawings, basic animation and rendering, 3D print preparation and cloud-enabled productivity.

Solid Edge Foundation

Our complete 3D CAD includes all the functionality of Solid Edge Design and Drafting, plus added sheet metal, frame and weldments, surface modeling, and plastic part design functionality. Plus, take advantage of built-in capabilities for basic FEA simulation for stress, motion and vibration.

Solid Edge Classic

Solid Edge Classic is everything you need in a 3D CAD package, including all the capabilities of Solid Edge Foundation, plus advanced features such as design for cost, reverse engineering (3D scanning), generative design, cam, gear, pulley and shaft design, spring design and beam and column design.

Solid Edge Premium

Our ultimate 3D CAD package, Solid Edge Premium includes everything included in the feature set of Solid Edge Classic, with the addition of advanced motion simulation, advanced stress simulation, simulation optimization, electrical routing, PCB collaboration and pipe and tube design.

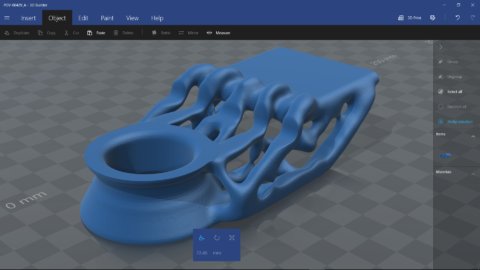

3D Printing

Create world class products using the latest techniques

Our tools support your end-to-end workflow, from design for 3D printing techniques to preparation and output to hardware and services with color printing capability.

Explore new concepts with generative design

Generative design combines powerful design tools with topology optimization, allowing you to quickly create light, highly customized complex shapes, uniquely suited for 3D printing.

Preparation of geometry for additive techniques

Seamlessly combine traditional “b-rep” solid models with triangular mesh models without time-consuming and error-prone conversions, reducing rework while supporting additive manufacturing processes for complex shapes.

Direct output of models to your 3D printer

Solid Edge supports output of your part models to 3D Printers using the 3D Print command. Write out your parts to .stl and .3MF formats, or send your parts directly to the Microsoft 3D Builder app. This allows you to print in-house with automated print preparation, including color printing capability.

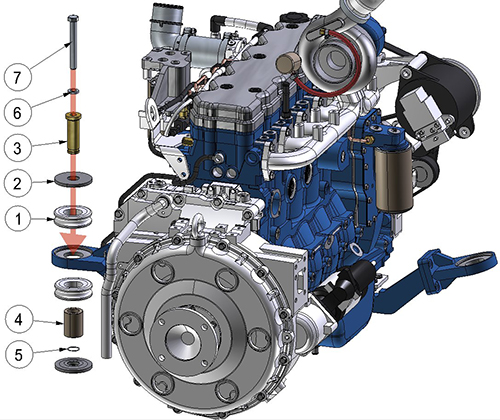

Computer Aided Manufacturing (CAM)

Build world class products accurately and efficiently using the latest manufacturing techniques

Solid Edge manufacturing solutions help manufacturers to define and execute a wide range of traditional and new manufacturing processes including CNC machining, nesting, cutting, bending, molding, welding, assembling, and additive manufacturing.

These software solutions work directly on your Solid Edge part, sheet metal and assembly models ensuring accurate and efficient manufacturing processes, and the manufacturing instructions created using these solutions can be easily updated to reflect any changes in the underlying design.

- Additive Manufacturing

- Feature-Based Machining

- Milling

- NS Simulation

- Turning

- 2D Nesting

Solid Edge CAM Pro

Designed with Solid Edge users in mind, Solid Edge CAM Pro features a rich set of tools to help you finish the job right the first time. Solid Edge CAM Pro is a modular, flexible configuration of numerical control (NC) programming solutions that allows you to maximize the value of your investments in the latest, most efficient and most capable machine tools. Easy to deploy and easy to learn, it provides powerful NC programming with a low total cost of ownership.

Ease-of-use

An intuitive, modern user interface (UI), easy-to-follow tutorials, built-in templates and wizard guides make Solid Edge CAM Pro remarkably easy to use. Consistent navigators manage key elements while dialogs provide graphical helpand instant feedback in the graphics area. Solid Edge CAM Pro also comes with fifteen built-in tutorials

Tight integration with Solid Edge

Sending files from Solid Edge Mechanical Design to Solid Edge CAM Pro is a one-button click. Send a single file or a whole manufacturing assembly. Data retains associativity, so that when late-stage design changes occur, they can be easily incorporated into the manufacturing plan.

CAD neutral capability

Understand influence of changes in the geometry or boundary conditions on the results by comparing a wide range of project variants. Assess results by numerical values, graphs or animations.

PMI functionality

Product Manufacturing Information (PMI) is transferred along with geometry data from Solid Edge to Solid Edge CAM Pro. That makes it easy for the NC Programmer to design the manufacturing plan according to the engineer’s specifications.

Postprocessor library

Included with Solid Edge CAM Pro, the Post Hub library enables a streamlined process to generate production-ready CNC programs for your applications. The searchable, online database lets you access more than 1,100 postprocessors directly from CAM Pro and download them to your workstation

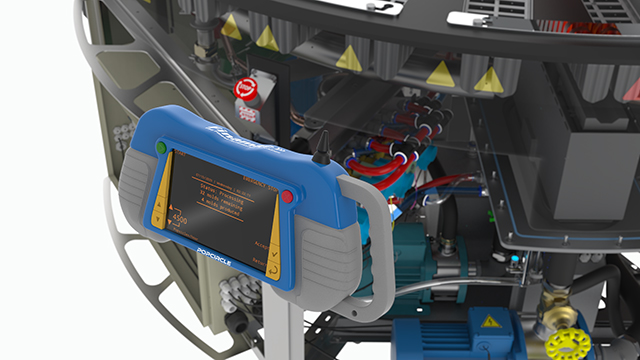

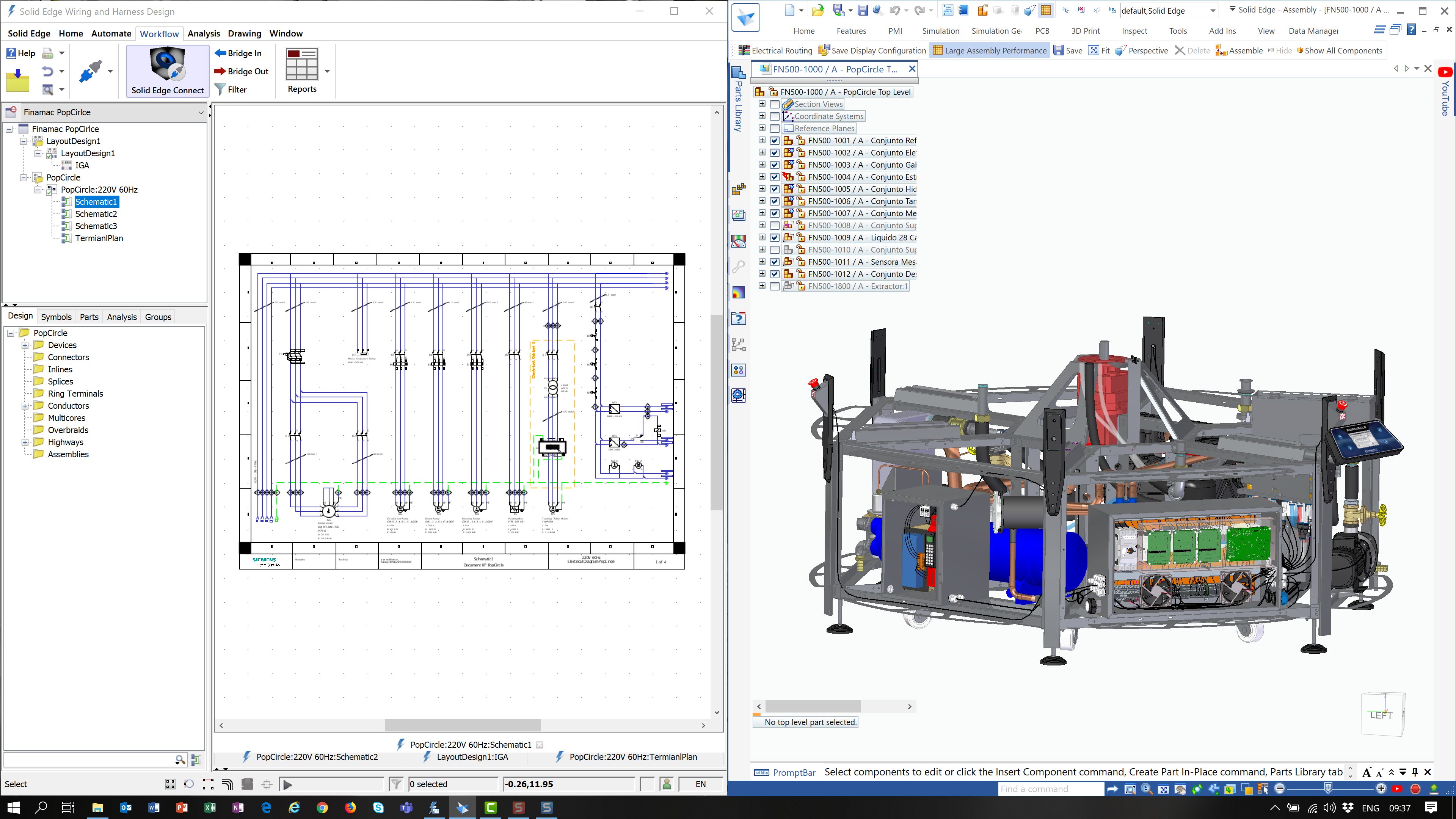

Electrical Design

Industry-proven electrical design tools, built by engineers for engineers, to simplify electrical design.

Industry-proven electrical design tools, built by engineers for engineers, to simplify electrical design.

Solid Edge helps you overcome electromechanical design challenges with a dedicated solution for electrical design—enabling true co-design collaboration across electrical and mechanical domains. Based on industry-leading technology, our products are trusted and proven around the world.

Model your design in 3D – Engineer the electrical details

Solid Edge solutions for electrical design allow you to:

- Design and simulate electrical systems, from simple electrical circuits to complex wire harnesses

- Route wiring and place components in 3D assembly models

- Prepare 2D industrial control panel layouts

- Analyze your models to calculate the correct wire lengths and wire harness designs

- Use virtual simulation to ensure circuitry performs per specification, without waiting for physical prototypes

- Interactively collaborate between ECAD and MCAD domains, even in disperse locations

- Visualize electrical aspects of your design in a 3D environment

- Fully integrate PCB layout and mechanical design environments

- Access robust libraries and parts repositories

- Increase productivity with full Teamcenter data synchronization

Solid Edge Wiring Design

A graphical design environment for creating wiring diagrams and service documentation. Features unique integrated electrical analysis and simulation that allow you to overcome electromechanical design challenges earlier in the design cycle. Includes configurable and re-usable layout design capabilities for use in the preparation of 2D industrial control panels.

Solid Edge Harness Design

A 2D graphical design environment for harness and formboard design. Automates the complete design-to-production flow. Automates the generation of full-scaled, manufacturing-ready drawings, a bill of materials and manufacturing reports, which significantly reduces production lead times and prevents manufacturing errors.

Solid Edge Electrical Routing

A dedicated, process-driven environment for the efficient creation, routing and organization of wires, cables and bundles in a mechanical assembly.Enables the transfer of harness topology data between MCAD-ECAD environments, reducing design time and manufacturing readiness. Unique connected mode feature highlights design changes in both environments through cross-probing. Live feedback immediately displays potential challenges.

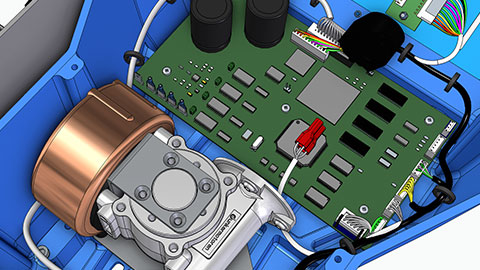

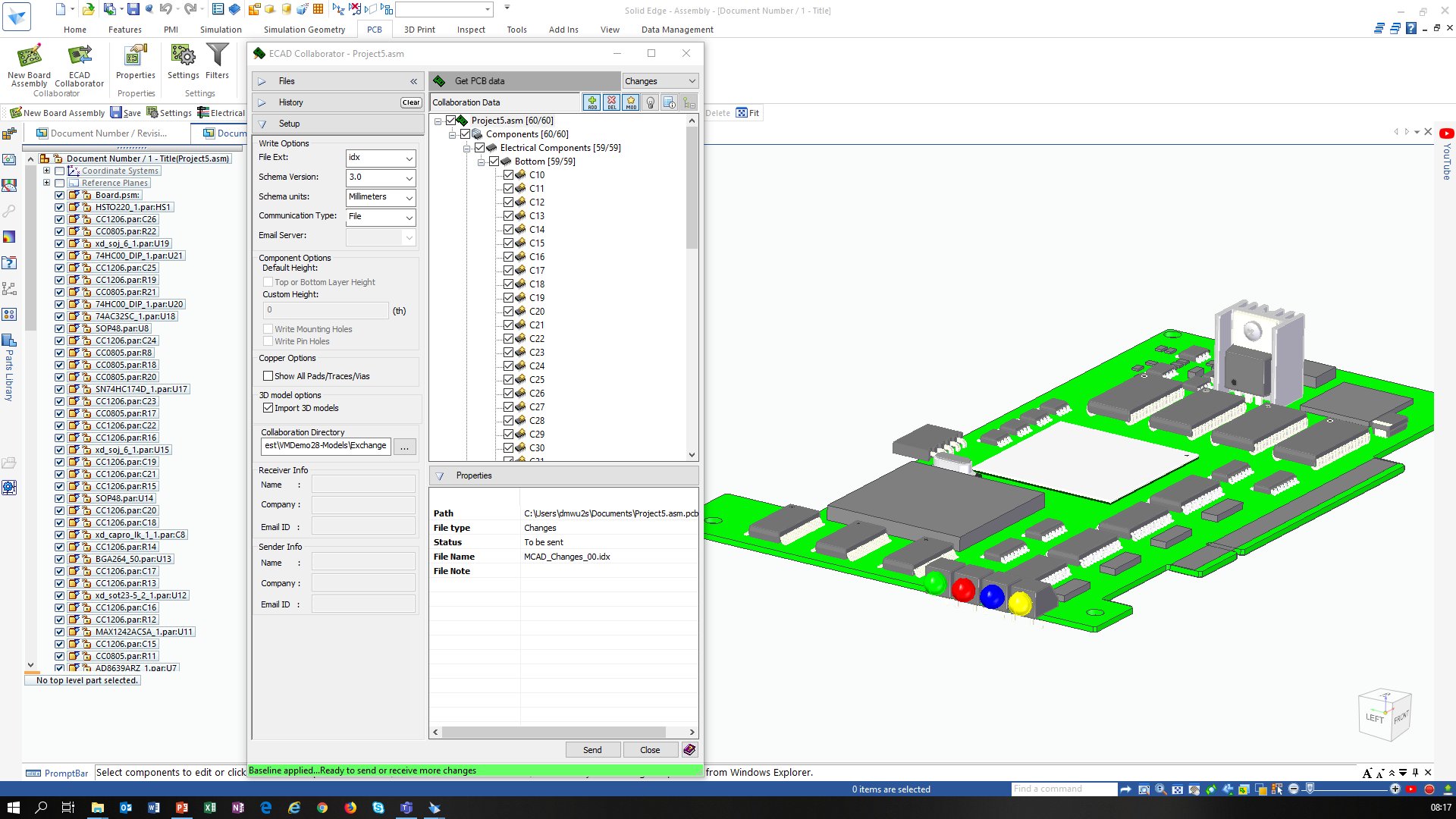

Solid Edge PCB Design

Schematic capture and PCB layout tools that simplify the complex task of printed circuit board design. Includes sketch routing, hierarchical 2D/3D planning and placement, and ECAD/MCAD collaboration.

Solid Edge PCB Collaboration

An open, interoperable collaboration environment for the development of printed circuit boards. Breaks down the communications barriers in PCB design by efficiently communicating design intent between ECAD and MCAD systems.

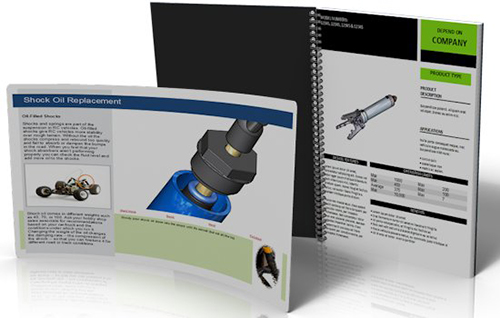

Technical Publications

Industry-proven electrical design tools, built by engineers for engineers, to simplify electrical design.

Industry-proven electrical design tools, built by engineers for engineers, to simplify electrical design.

Solid Edge helps you overcome electromechanical design challenges with a dedicated solution for electrical design—enabling true co-design collaboration across electrical and mechanical domains. Based on industry-leading technology, our products are trusted and proven around the world.

Work directly with your Solid Edge parts and assemblies

Solid Edge technical publications solutions are closely integrated with Solid Edge, allowing you to work directly with your Solid Edge parts and assemblies, and eliminating the need to convert your CAD files to a different format. And changes to the original design are easily incorporated into existing documents, speeding the engineering change process and ensuring that published documents reflect the current design.

Quickly create detailed illustrations of your designs

Solid Edge Illustrations allows you to create high-quality 3D PDF documents and cloud-ready illustrations from your Solid Edge files and other 3D CAD formats. Use Solid Edge to capture 3D views then add features including markups and balloons before publishing. Solid Edge Illustrations provides a complete image, animation and template-based 3D PDF creation package, making it easy to create high-quality communications from your 3D models.

Publish interactive technical documents

Solid Edge 3D Publishing is easy-to-use technical document authoring software that enables you to embed Solid Edge and other 3D CAD models directly into your documents. Solid Edge 3D Publishing includes a powerful set of tools for working with 3D CAD models, parts lists and formatted text allowing anyone to author complete printed or interactive technical documents in minutes. Perfect for creating training and work instructions, illustrated parts catalogs, service and support documentation, and product manuals.

Integration with Teamcenter PLM software

Shorten the cycle between design and documentation with Siemens world-class product lifecycle management (PLM) solution, Teamcenter®. Open, save, check-in and check-out the most recent version of your design data and perform additional data management tasks within the Teamcenter client.

The Teamcenter Integration for Solid Edge Technical Publications add-on enables direct access to your design data, ensuring you’re working with the right data, every time.

XLIFF Language Translation

Reach a larger, global market using XML Localization Interchange File Format (XLIFF) language translation to easily translate and localize digital documents. Available as an add-on, the Solid Edge XLIFF Language Translation module provides import/export functionally for language translation for both Solid Edge 3D Publishing and Solid Edge Illustrations.

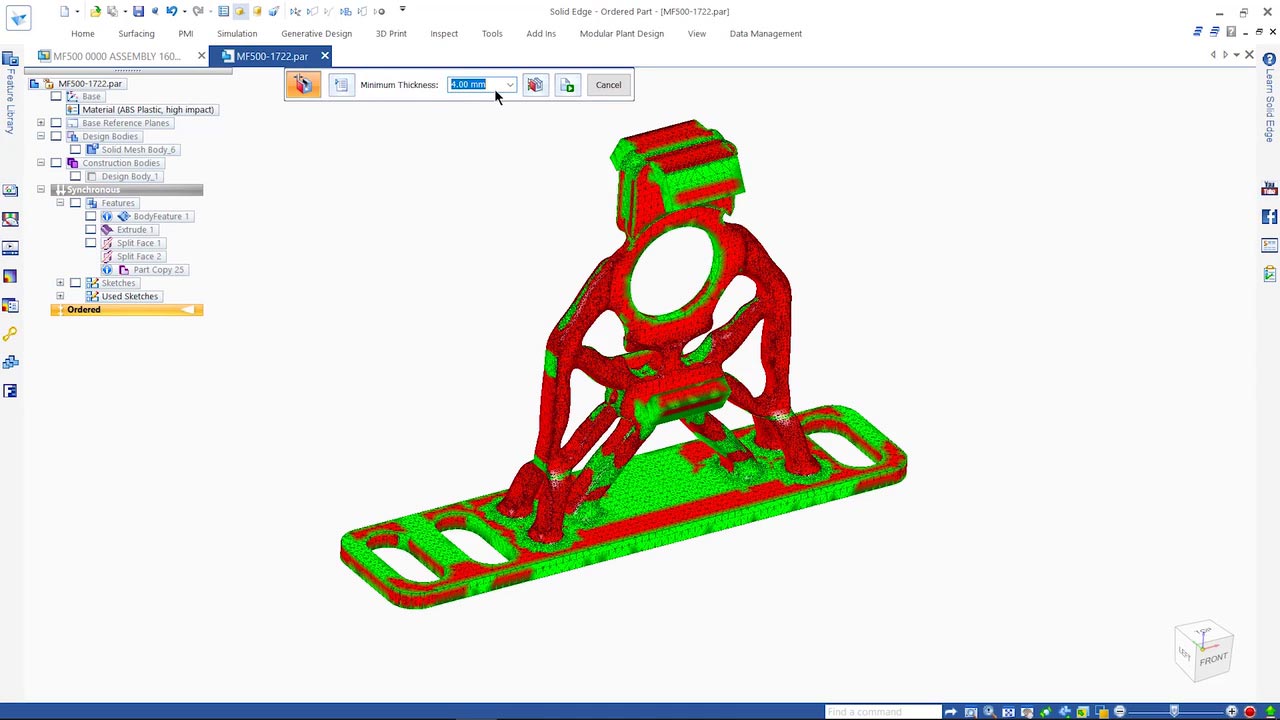

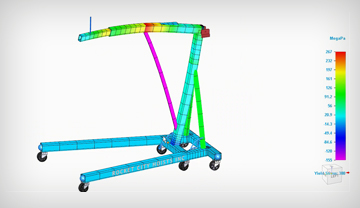

Simulation

Scalable simulation software changes the shape of design

"By starting simulation early in design, changes are made when they are easiest, time-to-manufacture is shortened, and cost-to-manufacture can be reduced. Accurate simulation of complete models reduces the number of physical prototypes and further reduces time and cost."

Work directly with your Solid Edge parts and assemblies

Simulation capabilities for Solid Edge users include simulation of individual parts, assembly analysis, definition and analysis of complete systems and computational fluid dynamics (CFD).

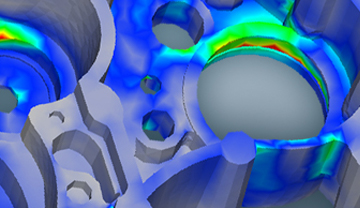

Solid Edge Simulation

Built-in finite element analysis (FEA) allows design engineers to digitally validate part and assembly designs within the Solid Edge environment. Solid Edge Simulation significantly reduces the need for physical prototypes, which lowers your material and testing costs, and saves design time.

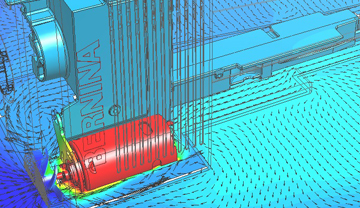

Simcenter FLOEFD for Solid Edge

Fully embedded in Solid Edge, Simcenter FLOEFD enables design engineers to frontload computational fluid dynamics (CFD) analysis or move simulation early into the design process where it can help examine trends and eliminate less desirable design options.

Femap

Affordable high performance FEA modeling for the engineering desktop. Femap is recognized as the world’s leading CAD-independent Windows-native pre- and post- processor for advanced engineering finite element analysis.

Partner Solutions

Further extend your capabilities with specialized partner solutions.

Solid Edge partners with many companies to create specialized apps to extend your capability. Solid Edge offers an open architecture and encourages other companies to join the program so customers have additional design options.

- Industial Design

- Analysis & Simulation

- Process Plant Design

- Electrical & Electronics

- Standard & Catalog Parts

- Manufacturing

- Design Management & Product Configuration

- Publishing

- Other